Revisão

| Replacing toxic nanomaterials in the textile industry: a review of recent advances and challenges |

|

Paola GracianoI; Gustavo S. MatiasII; Karen G. MierloII; Ana C. R. AranhaIII,* I Departamento de Administração, Universidade Estadual do Paraná, 83203-560 Paranaguá - PR, Brasil Received: 05/15/2025; *e-mail: carolraimundini@gmail.com The textile industry's reliance on nanotechnology, including in developing smart textiles, has raised significant concerns due to the improper disposal of toxic nanomaterials and the release of nanowaste into ecosystems. These challenges pose risks to human health and the environment, emphasizing the urgency of adopting sustainable practices aligned with global circular economy goals. This study aims to compile and analyze the existing research on nanotechnology to improve the sustainability of the textile supply chain. To fulfill this aim, a systematic literature review was guided by the PRISMA protocol and bibliometric and content analyses of articles published between 2004 and 2024, revealing key approaches such as green synthesis, advanced recycling methods, sustainable nanomaterial design, and efforts to replace hazardous substances. Despite these advancements, barriers related to cost, scalability, regulatory challenges, and stakeholder acceptance persist, limiting widespread implementation. This research provides valuable insights into environmentally conscious practices by bridging sustainability and nanotechnology. It supports adopting circular economy principles in textile production chains, contributing to the advancement of sustainable nanotechnology applications in the industry. INTRODUCTION Nanomaterials have significantly enhanced the functionality of textiles, driving innovation1,2 and advancing the development of smart textiles.3,4 These materials are commonly integrated into fiber production and finishing processes, offering a wide range of benefits. Smart textiles' most widely used nanomaterials include carbon nanotubes (CNTs), carbon nanofibers, metal oxides, clay nanoparticles, nano-cellular foams, and metal nanoparticles.5 Nanotechnology serves a variety of purposes in the textile industry, from the creation of specialized materials like tents and camouflage fabrics to the development of electronic conductive textiles.6 Conductive textiles, for example, can dissipate static charges, preventing electrical shocks, and can act as shields against harmful electromagnetic radiation, offering protection for both electronics and human health.7 Conductive nanofibers also show promise in healthcare applications, such as protective clothing, tissue engineering, and wound dressings.8 To enhance the durability of smart textiles, materials such as polybutyl acrylate, zinc oxide, aluminum oxide, silicon dioxide, and carbon nanotubes are often incorporated. These materials increase resistance to wear, water, and stains, thereby extending the lifespan of the textiles. Zinc oxide and aluminum oxide, in particular, are highly effective in providing self-cleaning, water-repellent, and stain-resistant properties.6 Among the main types of nanomaterials, carbon dark nanofibers and CNTs are the ones that show critical strength and malleable quality when strengthened in manufactured or standard fiber. One popular application of CNTs was in the design of high-performance athletic footwear, such as the Lone Star Spike by Adidas.6 CNTs are incorporated into the shoe design to improve flexibility, durability, and energy return, helping athletes achieve better performance by enhancing the shoe's responsiveness to track surface conditions.6 Despite these technological advancements, the sustainability of textiles, especially smart textiles, presents considerable challenges. Materials such as titanium dioxide, silver chloride, and carbon nanotubes can pose significant environmental and public health risks when improperly disposed of. The textile industry is a major contributor to nanomaterial pollution, particularly in aquatic ecosystems. This pollution occurs throughout the lifecycle of textiles, from production and wear to washing and disposal. Nanowaste can be released into the air, transported by wind, and eventually settle in aquatic systems or enter organisms through respiratory processes. Furthermore, nanomaterials can be directly discharged into water systems during production and washing processes.9 In the Brazilian context, the textile industry plays a significant role in the national economy and has been progressively integrating sustainability principles into its production chains. In recent years, initiatives have emerged focusing on nanowaste management and sustainable nanotechnology, including the development of eco-friendly nanomaterials through green synthesis and the valorization of agricultural residues, such as fruit peels and plant fibers, as raw materials. These practices not only align with global circular economy goals but also leverage Brazil's biodiversity and agricultural capacity to generate innovative, high-value materials. Such efforts position Brazil as a potential leader in sustainable textile nanotechnology, particularly in strategies that integrate environmental protection with socio-economic benefits.7-9 Due to their small size and high reactivity, nanoparticles present in nanowaste can potentially penetrate biological systems, causing toxicity.7 Nanoparticles made from metals, for instance, can infiltrate cell membranes and tissues, affecting organs like the lungs, liver, and brain. This can lead to cellular damage, inflammation, respiratory issues, neurological effects, and even cancer. In workplace environments, nanomaterial leakage can occur during textile handling processes, such as cutting or abrasion, releasing nanoparticles into the air and posing significant inhalation risks to workers. Additionally, the laundering of nanoparticle-embedded textiles and the improper disposal of these materials contribute to environmental contamination.10 The primary source of nanowaste is nanoplastics, which result from the fragmentation of plastic products.11 As these particles decrease in size, they pose a greater risk to biological systems, as smaller particles are more likely to penetrate and spread throughout the environment.12 Nanoplastics primarily affect aquatic organisms, disrupting behaviors, neurological functions, metabolism, and gut microbiomes.12,13 They can also impact the immune system, hormonal regulation, and reproduction of aquatic animals, inducing oxidative stress at the cellular level.13,14 Metal nanoparticles, particularly silver nanoparticles (AgNPs), are also significant environmental pollutants. Due to their high conductivity, these materials are commonly used in capacitors for smart textiles. However, they pose considerable toxicity to earthworms and other organisms, leading to a marked decline in soil fertility,15 besides ultimate human contamination.10 In response to these environmental concerns, recent advancements in nanotechnology have focused on enhancing the sustainability of textile production. By optimizing manufacturing processes to reduce the use of hazardous materials and designing products that require fewer nanomaterial,7 the industry is moving toward more sustainable practices. The adoption of more sustainable nanoparticles offers a promising alternative to traditional chemical treatments, which are more polluting and less efficient.16 This emerging area of research, however, remains underexplored, with limited studies on how sustainable nanomaterials can mitigate environmental impacts across the textile supply chain. In light of this, this review aims to address the research question: "What are the nanotechnology strategies that can be employed to mitigate the environmental impact of nanowaste in the textile industry?". To answer this question, this study aims to compile and analyze the existing research on nanotechnology to improve the sustainability of the textile supply chain, presenting the latest advancements in nanotechnology for textiles, along with trends and insights from current research. The study begins with a bibliometric analysis to provide an overview of the key features and trends in this field. Next, the PRISMA protocol17-19 is applied to select relevant articles for content analysis. Finally, the review discusses potential directions for future research, identifying gaps in the existing literature and proposing areas for further exploration.

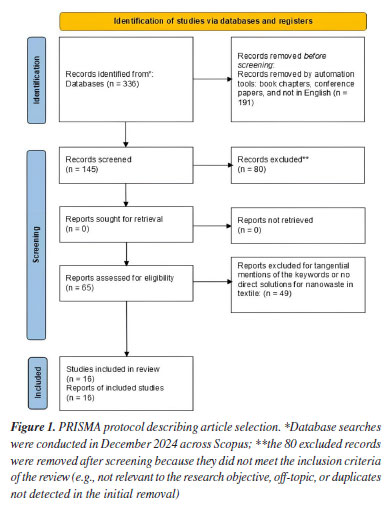

METHODS To address the study's objectives, a systematic methodology was developed to collect data, select documents for analysis, and refine the research question. To achieve these goals, we conducted a systematic literature review (SLR), which involved identifying, evaluating, and interpreting all available research relevant to the topic.17-19 The study employed the methodological sequence proposed by Denyer and Tranfield:20 (i) data collection, (ii) bibliometrics, and (iii) content analysis. In step (i), to select relevant articles, we followed the PRISMA guidelines,17-19 employing a systematic approach to ensure transparency and reproducibility in the selection process. The following search string was applied to titles, abstracts, and keywords: ("Textile" AND ("smart" OR "nanotechnology") AND ("sustainability" OR "waste management" OR "circular economy")). Database searches were conducted in December 2024 across Scopus. Initially, no restrictions were placed on the publication date. However, due to the limited number of publications before 2004 and the tendency of rapid growth in related technological fields,21 we narrowed the time frame to 2004-2024. Scopus was selected as the primary database, as it aggregates a significant portion of internationally published articles.22 The initial search retrieved 336 documents. Of these, 191 were excluded for various reasons, including being book chapters, conference papers, or non-English documents. These exclusions were based on the lack of peer review and potential language barriers. Following this filtering process, 145 peer-reviewed articles remained for bibliometric analysis. During the bibliometric step (ii), the collected data were exported from the Scopus database in BibTex format for analysis. The BibTex format was chosen for its compatibility with the Bibliometrix package,23 which was used to conduct the bibliometric research. Bibliometrix provides tools for quantitative analysis, including publication history, co-occurrence networks, thematic maps, and conceptual structure maps,23 all of which were utilized in this study to explore research trends and thematic developments. For the content analysis in step (iii), we screened the collection of articles based on their titles, abstracts, and keywords to evaluate their relevance to our research question: "What nanotechnology strategies can be employed to mitigate the environmental impact of nanowaste in the textile industry?". Articles were selected for further reading if at least one of these fields contained relevant information. Conversely, documents that showed no connection to the study's objectives were excluded. This process resulted in the removal of 80 documents, leaving 65 articles for in-depth content analysis. Finally, for content analysis, 49 of the 65 documents were excluded as they did not provide direct contributions to nanowaste management in smart textiles. Many of these documents either failed to address nanomaterials specifically or only mentioned the terms of interest tangentially. While some highlighted the importance of the theme, they lacked actionable strategies for addressing the issue. This refinement resulted in a final collection of 16 documents that offered specific and direct insights into nanowaste management in the smart textile industry. The complete process of article selection is described in Figure 1.

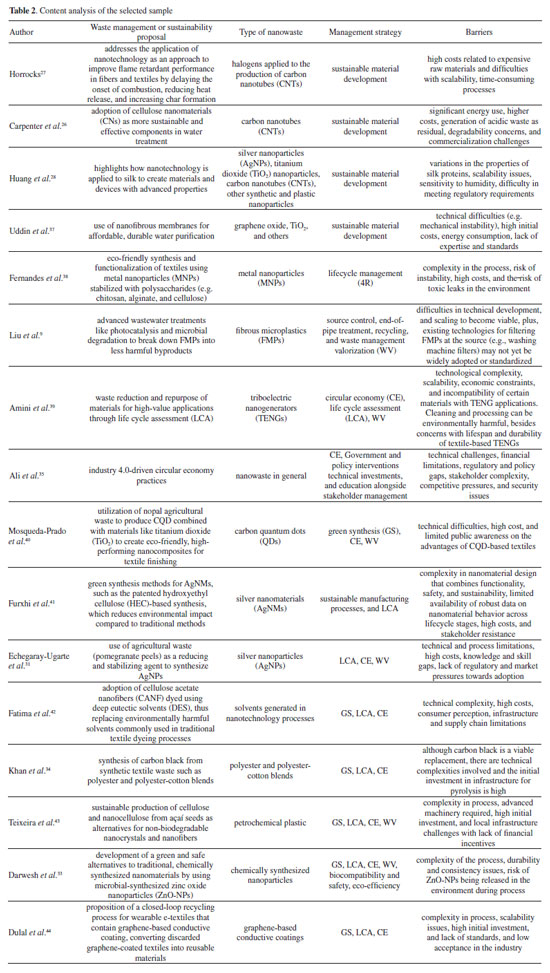

We conducted a full reading of the selected articles to extract relevant information comprehensively. Following the steps for content analysis suggested by Elo and Kyngäs,24 we categorized the articles into four key areas: (i) waste management or sustainability proposal; (ii) type of nanomaterial targeted; (iii) management strategies applied, and (iv) barriers for implementation. Finally, the findings and conclusions derived from this analysis are presented and discussed.

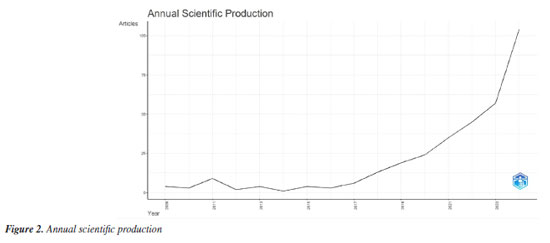

RESULTS AND DISCUSSION Current research dynamics in smart textiles - nanotechnology, and waste management Scientific production over time As anticipated, the history of scientific production on nanowaste management in textiles is relatively recent. Between 2004 and 2017, the field registered an average of four articles per year. A notable surge occurred in 2018, with 13 articles published, followed by a near tripling to 53 articles in 2023. To better illustrate this growth, 2009 was selected as an inflection point, marking a shift in the dynamics of publication growth - likely reflecting increased interest in the topic. By 2024, the trend of significant growth continued, with 104 articles published addressing at least one of the themes of interest. This progression is illustrated in Figure 2.

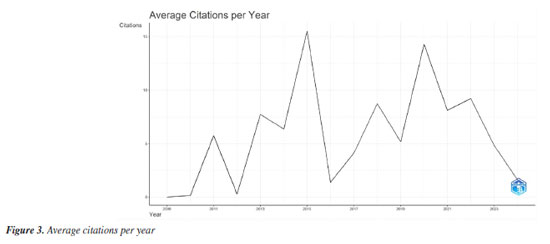

The increasing number of articles published each year, as shown in Figure 3, may have contributed to a decrease in the average citations per article. This trend could be attributed to the dilution effect, as more authors contribute to the pool of references, leading to citations being spread across a broader range of studies. Additionally, the growth in publications may result in reduced novelty or narrower research scopes for individual studies, further influencing citation patterns. However, other factors, such as shorter citation windows or shifts in research priorities, may also play a role in this decline.

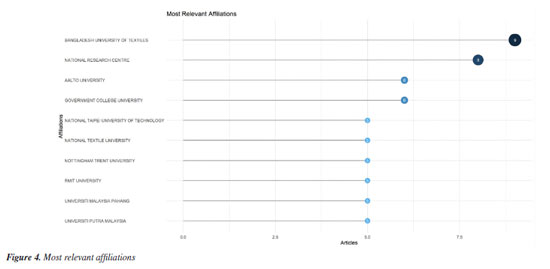

Next, we analyzed the main authors and their affiliations to identify leading universities and geographic hubs contributing to this field of research. As shown in Figure 4, the data reveals a predominance of Asian authors, with significant contributions from India (139 documents), China (79 documents), and Pakistan (32 documents). Other major contributors include the United Kingdom (56 documents), the United States (56 documents), and Italy (35 documents). This geographic distribution reflects the prominence of regions with strong industrial and academic focus on nanotechnology and textile innovation.

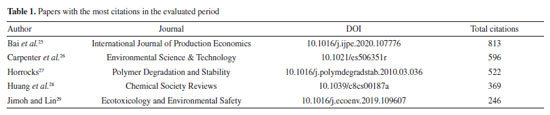

Another important metric is the most cited papers in the field. Table 1 presents the five most globally cited papers in the themes of interest. However, it is important to emphasize that some of these articles, while relevant, did not specifically address the research question that guided our study. Their frequent citation may be attributed to their overall influence and/or pioneering contributions to the broader collection of articles that explored the theme we focused on.

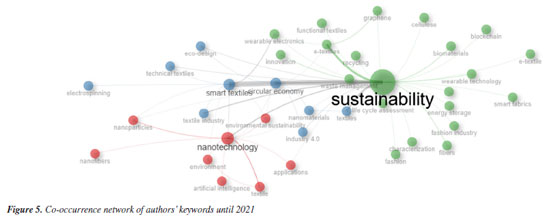

The most cited paper was "Industry 4.0 Technologies Assessment: A Sustainability Perspective" from Bai et al.25 This study explored industry 4.0 technologies, aiming at specific sustainability objectives and calling attention to the textile, apparel, and footwear industry as sectors that could be highly impacted by the adoption of industry 4.0 disruptive new technologies. The second position belongs to "Cellulose Nanomaterials in Water Treatment Technologies" by Carpenter et al.26 This paper explores the adoption of cellulose nanomaterials (CNs) as more sustainable and effective components in water treatment and its efficiency in replacing carbon nanotubes (renewable, highly polluting, and also more costly). This study is from 2015 and represents one of the first attempts to solve nanowaste issues in the textile industry. The third most cited document was "Flame Retardant Challenges for Textiles and Fibres: New Chemistry versus Innovatory Solutions" by Horrocks.27 This is a 2015 article that explored the dynamics of flame retardants (FRs) development for textiles and fibers over time. It pointed to nanoparticles (such as clays and silicas) as alternatives for surface treatments and coatings able to enhance fire resistance with minimal environmental impact due to their bio-based nature in contrast to highly hazardous halogens (most commonly used). The fourth most cited study was "Silkworm Silk-Based Materials and Devices Generated using Bio-Nanotechnology" by Huang et al.28 This explored the nanofabrication techniques with several different approaches, such as electrospinning, lithography, and 3D printing, which are used to create silk-based nanostructures. This research emphasizes the application of these nanostructures in biomedical apparel due to their biodegradable properties. Finally, the fifth most cited article was "Biosurfactant: A New Frontier for Greener Technology and Environmental Sustainability" by Jimoh and Lin.29 This study highlights biosurfactants as eco-friendly, biodegradable, and sustainable alternatives to traditional chemical surfactants. As nanoparticles tend to clump together, altering their toxicity and mobility, biosurfactants can act coating on the particles, maintaining their dispersion and reducing the risk of concentrated toxicity in specific locations. Co-occurrence network A keyword co-occurrence network (KCN) analyzes the connections between keywords used by authors in the literature to understand the knowledge components and structure of a scientific or technical field.23 In our co-occurrence network, the criterion for keyword selection was the author's keywords. Figure 5 illustrates the co-occurrence network formed by the articles in our collection, which reveals three distinct networks of terms. The red network, for instance, is centered around nanotechnology and includes various processes involved in the production of nanomaterials, making it a cluster with a strong technical focus.

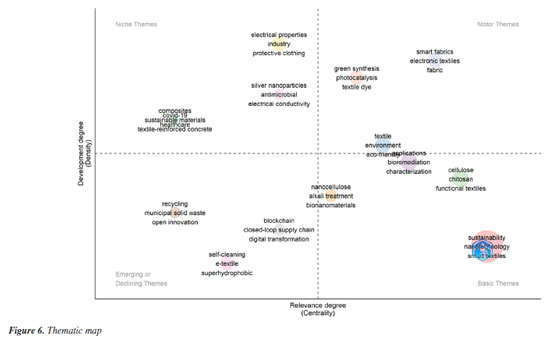

As depicted in Figure 5, the green cluster represents a network of articles that address concerns related to sustainability in the textile industry. These studies primarily focus on sustainability issues in the textile supply chain, though they do not necessarily offer solutions to the specific issue of nanowaste. The blue cluster, on the other hand, is sparser and more isolated from the other clusters, consisting mainly of niche-related terms. As a result, we observe a lack of direct connections between sustainability and nanotechnology in textiles. Overall, while the studies addressed the three thematic clusters individually, few provided an integrated view of all three. Thematic map Thematic maps indicate four stages of themes concerning academic interest: the upper right quadrant represents the key topics explored so far in the literature on a given field of research. The upper left quadrant points to niche themes, which are subjects that are of interest to specific clusters of researchers. The bottom left themes relate to either ascendant interest or decay. Finally, the bottom right quadrant indicates themes considered basic knowledge in the field.30 Examining the thematic map of nanowaste research in the textile industry (Figure 6), we can conclude that the motor themes align with some of the key objectives of nanowaste research. For example, terms such as "green synthesis" - explored by Echegaray-Ugarte et al.,31 who investigated the green synthesis of silver nanoparticles (AgNPs) using pomegranate peel extract, and their incorporation into NRL nanofibers - and "photocatalysis", a technique used for water purification derived from industrial processes, were prominent.32

Smart fabrics were another term that ascended in the collection. Its mentions were mostly accompanied by environmental concerns with textile waste. Interestingly, the eight studies that explored such issues were published in 2024 (e.g. Darwesh et al.,33 Khan et al.34), reinforcing the novelty of this concern in research and its ascension in scholarly attention. At the same time, environmental concerns in the textile industry are becoming a basic theme, since its exploration has been an issue before the uprising of nanotechnology for fabrics. Meanwhile, the bottom left quadrant exhibits themes that are starting to capture scholar's interest. They mainly refer to new technological possibilities in nanotechnology and the association of digital improvements (represented by "blockchain", "digital transformation" and "e-textiles"). Moving to the upper left quadrant, there is a predominance of topics that are especially complex and, thus, niche. It means researchers involved in these themes are concentrated on technical developments in a specific field because these are nascent technologies that have not matured yet or gained wider attention from the scientific community. For instance, the two studies on the synthesis of silver nanoparticles from textiles are from 2024 (as verified in the content analysis section). Due to its relevance for sustainable practices in dyeing procedures, it is expected that the subject will keep gaining more momentum and moving to the mother themes' quadrant in the coming years. These results allow for the interpretation that the term "sustainability" is hardly a declining theme, being most likely in an ascending trajectory. Several studies emphasize innovative recycling techniques for smart textiles, indicating that sustainability practices are becoming increasingly mainstream in textile production. Moreover, rising public awareness about environmental issues has propelled research that aligns with sustainable waste management practices, further establishing this theme within the academic discourse.33,35,36 As expected by the results found in the "Co-occurrence network" sub-section, the research on sustainability in textiles is separated from the research in nanotechnology, meaning the sustainable approach currently present in the textile industry regarding nanowaste is still in its infancy. Nanowaste sustainable solution and barriers for adoption Documents were analyzed through four criteria: waste management or sustainability proposal, type of nanowaste targeted, management strategies, and barriers for implementation. The findings are exhibited in Table 2.

The analysis of sustainability proposals in nanowaste management highlights a strong focus on developing sustainable materials and innovative strategies. Approaches such as green synthesis, lifecycle management, and circular economy principles are central to the discourse. For example, Furxhi et al.41 emphasized green synthesis methods, including the use of hydroxyethyl cellulose (HEC) to produce silver nanomaterials, as a safer alternative to traditional approaches. However, these methods face persistent challenges in scalability and cost-effectiveness, as evidenced by the complexities and costs associated with synthesizing cellulose nanomaterials.43 Overcoming these barriers is crucial for translating laboratory research into industrial applications. Overall, the barriers identified are related to high costs, particularly initial investments, scalability, market acceptance, health and safety regulatory standards, process complexity, and competition with established materials.9 For example, Fatima et al.42 demonstrated that cellulose acetate nanofibers (CANFs) dyed with deep eutectic solvents face technical complexity and supply chain limitations, which hinder their adoption. Similarly, Darwesh et al.33 noted that microbial-synthesized ZnO-NPs, while eco-efficient, struggle with consistency and durability, leading to increased reluctance among stakeholders to embrace these materials. Substantial investments in research are needed to overcome these challenges by reducing costs and enhancing the technical viability of these processes. The use of life-cycle assessment (LCA) was frequently observed in the studies. Research integrating LCA into circular economy frameworks, such as that by Echegaray-Ugarte et al.31 and Mosqueda-Prado et al.,40 reveals the potential to reclaim valuable materials like silver nanoparticles and carbon quantum dots (QDs) through waste valorization. While these approaches are promising, they require standardized methodologies and expanded data to effectively inform policy and industrial implementation. Circular economy practices were also frequently mentioned in the studies. Its potential is particularly evident in research utilizing agricultural waste and renewable resources to produce nanomaterials. For instance, Teixeira et al.43 demonstrated how nanocellulose extracted from açaí seeds could replace petrochemical-derived materials, reducing environmental impact while supporting local economies. Similarly, Echegaray-Ugarte et al.31 produced silver nanoparticles using pomegranate peels, highlighting the dual benefits of waste reduction and added value. However, these methods require significant investments in advanced infrastructure and machinery, which pose substantial barriers to scalability.40 Integrating such solutions into production chains will depend on overcoming these economic and technical challenges. Additionally, Horrocks27 demonstrated how nanoclays and nanosilicas improve flame retardancy in textiles while reducing the environmental impact of traditional halogenated treatments used in the production of carbon nanotubes. Similarly, Mosqueda-Prado et al.40 highlighted the development of quantum dots (QDs) derived from nopal waste to create multifunctional textiles with enhanced fluorescence properties. Despite the promising advances, a critical gap in integrating sustainability practices with effective nanowaste management in the textile industry remains. The transition from petroleum-based plastics to biodegradable materials, such as those developed by Teixeira et al.,43 demonstrates how waste can be transformed into income-generating products for local communities. Moreover, Mosqueda-Prado et al.40 and Echegaray-Ugarte et al.31 emphasized the potential for agricultural waste valorization to create high-performance nanomaterials while alleviating environmental challenges. Such approaches are pivotal in pursuing sustainability goals within the textile industry. Finally, the limited scalability of nanotechnology applications in textiles underscores the need for collaboration between government and industry to address regulatory and financial barriers. Furxhi et al.41 highlighted the importance of safe-by-design frameworks that integrate safety considerations into early nanomaterial development, which could reduce risks as the technology scales. Moreover, digital tools like blockchain for lifecycle tracking could improve transparency and accountability in textile supply chains. By aligning technological innovation with robust policy measures, the textile industry can transition toward a more sustainable future, balancing environmental, economic, and social goals to create lasting change.

CONCLUSIONS This study aimed to compile and analyze existing research on nanotechnology as a tool for enhancing the sustainability of the textile supply chain. To achieve this, a systematic literature review was conducted, following the PRISMA protocol and employing bibliometric and content analyses of articles published between 2004 and 2024. The methodology included three key steps: data collection, bibliometrics, and content analysis. The final sample of 16 articles revealed that approaches linking "sustainability" to "nanowaste" in the textile sector are still emerging, with research interest reaching a notable peak in 2024. Given the significant environmental and societal risks posed by certain nanomaterials, it is anticipated that publications on this topic will continue to rise. Additionally, further research is expected to focus on overcoming key barriers, such as high costs, stakeholder engagement, and expertise gaps, which currently hinder the widespread adoption of more sustainable methods. Despite these challenges, progress has been made, and the identified barriers could serve as valuable areas for future research, particularly about circular economy models and life cycle assessment in the context of nanowaste. This study offers several contributions. Theoretically, it identifies key barriers to advancing more sustainable practices in the application of nanotechnology in textiles. These findings open up several avenues for future research, such as (i) evaluating the social benefits of waste utilization, particularly how families could generate income from it; (ii) conducting case studies with textile companies to assess their disposal guidelines and willingness to test new approaches; and (iii) employing decision-making tools to identify the most viable solutions based on each company's budget and specific needs. From a practical standpoint, the study encourages prioritizing innovative solutions to enhance the circularity of nanomaterials in textile production chains. Corporate R&D and academic research should focus on developing cost-effective alternatives, while management scholars explore innovation, competitive differentiation, supply chain diffusion of new practices, and stakeholder commitment to sustainability. Given the significant externalities associated with nanowaste, governmental support is essential to advance alternative materials and implement targeted regulatory measures. This study has several limitations. First, the data collection was limited to the Scopus database, which may have excluded relevant studies not indexed there. Second, only two researchers participated in the article selection process for content analysis, which increases the potential for bias, as no third-party judgment was involved, and only articles both researchers agreed upon were included. Future research should aim to address these limitations and expand knowledge in the field. Suggested directions include integrating life cycle assessment (LCA) and circular economy frameworks to assess the environmental impact of nanowaste reduction strategies, investigating the feasibility of sustainable nanomaterial applications across various industrial contexts, and developing interdisciplinary approaches to link technological advancements with socio-economic benefits. Additionally, further exploration of regulatory strategies and their implementation in the textile industry could offer clearer guidance on achieving sustainability goals.

DATA AVAILABILITY STATEMENT All data generated or analyzed during this study are included in this published article.

ACKNOWLEDGMENTS This work was supported by the Coordination for the Improvement of Higher Education Personnel - CAPES.

REFERENCES 1. Shah, M. A.; Pirzada, B. M.; Price, G.; Shibiru, A. L.; Qurashi, A.; J. Adv. Res. 2022, 38, 55. [Crossref] 2. Syduzzaman; Hassan, A.; Anik, H. R.; Akter, M.; Islam, R.; ChemNanoMat 2023, 9, e202300205. [Crossref] 3. Perry, A.; International Journal of Fashion Design, Technology and Education 2017, 11, 129. [Crossref] 4. Rotzler, S.; Malzahn, J.; Werft, L.; von Krshiwoblozki, M.; Eppinger, E.; Textiles 2022, 2, 524. [Crossref] 5. Yetisen, A. K.; Qu, H.; Manbachi, A.; Butt, H.; Dokmeci, M. R.; Hinestroza, J. P.; Skorobogatiy, M.; Khademhosseini, A.; Yun, S. H.; ACS Nano 2016, 10, 3042. [Crossref] 6. Jatoi, A. S.; Khan, F. S. A.; Mazari, S. A.; Mubarak, N. M.; Abro, R.; Ahmed, J.; Ahmed, M.; Baloch, H.; Sabzoi, N.; Nanosensors and Nanodevices for Smart Multifunctional Textiles; Ehrmann, A.; Nguyen, T. A.; Nguyen, T. P., eds.; Elsevier, 2021, p. 343. [Crossref] 7. Fu, K.; Padbury, R.; Toprakci, O.; Dirican, M.; Zhang, X.; Engineering of High-Performance Textiles; Miao, M.; Xin, J. H., eds.; Woodhead Publishing, 2018, p. 305. [Crossref] 8. Nathanael, A. J.; Oh, T. H.; Crystals 2021, 11, 199. [Crossref] 9. Liu, S.; Liu, S.; Xiao, X.; Liu, L.; Peijnenburg, W.; Xu, Y.; Wang, Y.; Yu, Y.; Li, L.; She, X.; Aquat. Toxicol. 2024, 276, 107119. [Crossref] 10. Donaldson, K.; Stone, V.; Tran, C. L.; Kreyling, W.; Borm, P. J. A.; Occup. Environ. Med. 2004, 61, 727. [Crossref] 11. Barnes, D. K. A.; Galgani, F.; Thompson, R. C.; Barlaz, M.; Philos. Trans. R. Soc., B 2009, 364, 1985. [Crossref] 12. Jacob, H.; Besson, M.; Swarzenski, P. W.; Lecchini, D.; Metian, M.; Environ. Sci. Technol. 2020, 54, 4733. [Crossref] 13. Barboza, L. G. A.; Vieira, L. R.; Branco, V.; Figueiredo, N.; Carvalho, F.; Carvalho, C.; Guilhermino, L.; Aquat. Toxicol. 2018, 195, 49. [Crossref] 14. Kögel, T.; Bjorøy, Ø.; Toto, B.; Bienfait, A. M.; Sanden, M.; Sci. Total Environ. 2020, 709, 136050. [Crossref] 15. Diez-Ortiz, M.; Lahive, E.; George, S.; Schure, A. T.; Van Gestel, C. A. M.; Jurkschat, K.; Svendsen, C.; Spurgeon, D. J.; Environ. Pollut. 2015, 203, 191. [Crossref] 16. Provin, A. P.; Dutra, A. R. A.; Machado, M. M.; Cubas, A. L. V.; J. Cleaner Prod. 2021, 282, 124444. [Crossref] 17. Matias, G. S.; Lermen, F. H.; Bissaro, C. A.; Nicolin, D. J.; Fischer, C.; Jorge, L. M. M.; J. Food Process Eng. 2022, 45, e14060. [Crossref] 18. Kuakoski, H. S.; Lermen, F. H.; Graciano, P.; Lam, J. S. L.; Mazzuchetti, R. N.; Maritime Policy & Management 2023, 51, 1517. [Crossref] 19. Cordeiro, E. R.; Lermen, F. H.; Mello, C. M.; Ferraris, A.; Valaskova, K.; Journal of Knowledge Management 2024, 28, 590. [Crossref] 20. Denyer, D.; Tranfield, D.; The Sage Handbook of Organizational Research Methods; Buchanan, D. A.; Bryman, A., eds.; Sage: Thousand Oaks, USA, 2009, p. 671. 21. Hook, D. W.; Porter, S. J.; Draux, H.; Herzog, C. T.; Frontiers in Research Metrics and Analytics 2021, 5, 595299. [Crossref] 22. Cuccurullo, C.; Aria, M.; Sarto, F.; Scientometrics 2016, 108, 595. [Crossref] 23. Aria, M.; Cuccurullo, C.; Journal of Informetrics 2017, 11, 959. [Crossref] 24. Elo, S.; Kyngäs, H.; Journal of Advanced Nursing 2008, 62, 107. [Crossref] 25. Bai, C.; Dallasega, P.; Orzes, G.; Sarkis, J.; International Journal of Production Economics 2020, 229, 107776. [Crossref] 26. Carpenter, A. W.; de Lannoy, C.-F.; Wiesner, M. R.; Environ. Sci. Technol. 2015, 49, 5277. [Crossref] 27. Horrocks, A. R.; Polym. Degrad. Stab. 2011, 96, 377. [Crossref] 28. Huang, W.; Ling, S.; Li, C.; Omenetto, F. G.; Kaplan, D. L.; Chem. Soc. Rev. 2018, 47, 6486. [Crossref] 29. Jimoh, A. A.; Lin, J.; Ecotoxicol. Environ. Saf. 2019, 184, 109607. [Crossref] 30. Wang, Y.; Ren, J.; Ye, C.; Pei, Y.; Ling, S.; Nano-Micro Lett. 2021, 13, 72. [Crossref] 31. Echegaray-Ugarte, T. S.; Cespedes-Loayza, A. L.; Cruz-Loayza, J. L.; Huayapa-Yucra, L. A.; Cruz, I.; de Carvalho, J. C.; Goyzueta-Mamani, L. D.; Polymers 2024, 16, 1531. [Crossref] 32. Song, M.; Jiang, J.; Zhu, J.; Zheng, Y.; Yu, Z.; Ren, X.; Jiang, F.; Carbohydr. Polym. 2021, 272, 118460. [Crossref] 33. Darwesh, O. M.; Matter, I. A.; Al-Balakocy, N. G.; Abo-Alkasem, M. I.; Sci. Rep. 2024, 14, 16660. [Crossref] 34. Khan, A.; Awais, M.; Mohsin, M.; Biomass Convers. Biorefin. 2024, 14, 23485. [Crossref] 35. Ali, S. S.; Torğul, B.; Paksoy, T.; Luthra, S.; Kayikci, Y.; Business Strategy and the Environment 2024, 33, 7825. [Crossref] 36. Amjad, F.; Baig, S. A.; Basit, A.; Usman, M.; J. Text. Inst. 2024. [Crossref] 37. Uddin, Z.; Ahmad, F.; Ullan, T.; Nawab, Y.; Ahmad, S.; Azam, F.; Rasheed, A.; Zafar, M. S.; Int. J. Environ. Sci. Technol. 2022, 19, 9149. [Crossref] 38. Fernandes, M.; Padrão, J.; Ribeiro, A. I.; Fernandes, R. D. V.; Melro, L.; Nicolau, T.; Mehravani, B.; Alves, C.; Rodrigues, R.; Zille, A.; Nanomaterials 2022, 12, 1006. [Crossref] 39. Amini, S.; Ahmed, R. F. S. M.; Kumar, S.; Ankanathappa, S. M.; Sannathammegowda, K.; Waste Manage. 2024, 190, 477. [Crossref] 40. Mosqueda-Prado, J. B.; Pinillos-Bernal, E.; Ospina-Montoya, V.; Vásquez-Rendón, M.; Forgionny, A.; Acelas, N.; Front. Mater. 2024, 11, 1478418. [Crossref] 41. Furxhi, I.; Perucca, M.; Koivisto, A. J.; Bengalli, R.; Mantecca, P.; Nicosia, A.; Burrueco-Subirà, D.; Vázquez-Campos, S.; Lahive, E.; Blosi, M.; de Ipiña, J. L.; Oliveira, J.; Carriere, M.; Vineis, C.; Costa, A.; Comput. Struct. Biotechnol. J. 2024, 25, 127. [Crossref] 42. Fatima, W.; Tarique, M.; Hussain, S.; Shi, X.; Wang, X.; Ahmed, W.; Kim, I.; Wei, K.; Fibers Polym. 2024, 25, 1325. [Crossref] 43. Teixeira, L. H. C.; de Morais, M. G.; Costa, J. A. V.; Biomass Convers. Biorefin. 2025, 15, 12801. [Crossref] 44. Dulal, M.; Afroj, S.; Islam, M. R.; Zhang, M.; Yang, Y.; Hu, H.; Novoselov, K. S.; Karim, N.; Small 2024, 20, 2407207. [Crossref] |

On-line version ISSN 1678-7064 Printed version ISSN 0100-4042

Qu�mica Nova

Publica��es da Sociedade Brasileira de Qu�mica

Caixa Postal: 26037

05513-970 S�o Paulo - SP

Tel/Fax: +55.11.3032.2299/+55.11.3814.3602

Free access